Professional Industry CIP system Cleaning in place equipment hot sell in Netherlands ZZ

- * Processing : CIP system,cleaning in place system,CIP equipment

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

Our equipment ranges from 50L to several tons, and can be designed and produced for customers according to their needs.

CIP systemcleaning in place equipmentCip system hot sell in Netherlandsprofessional Cleaning in place equipment

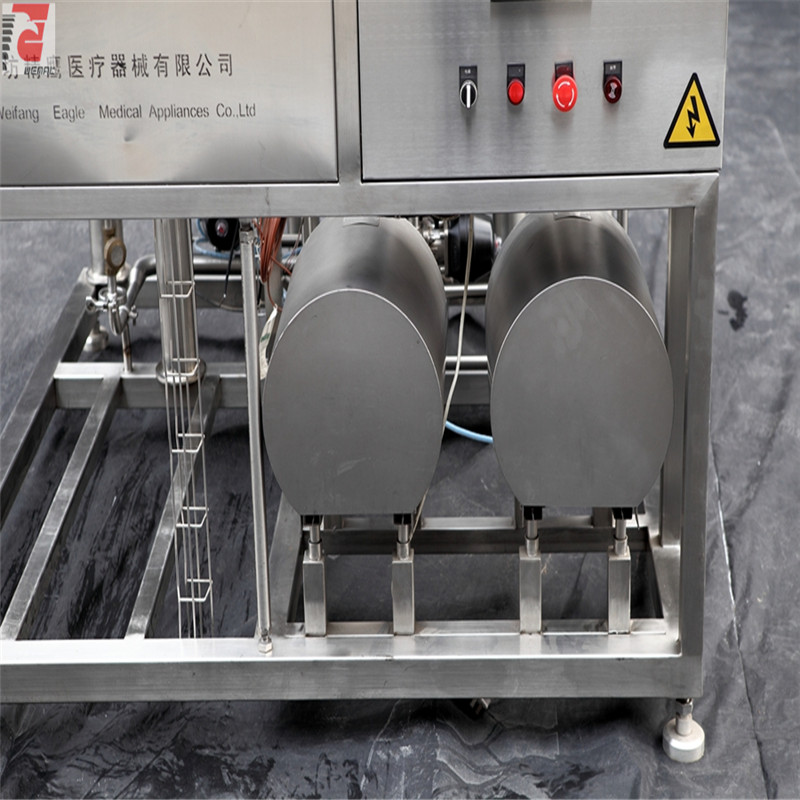

This picture shows the 50L Small size cleaning system,the two tanks in this set of equipment are hot water tank and acid water tank,equipment with manual valve in the pipes and the whole set of equipment are made of high quality stainless steel,and the equipment are used in beer brewing system,after the brewing process finished,this set of equipment is used to cleaning the tanks

Features of automatic CIP cleaning system

1. The automatic CIP cleaning system has low economic operation cost, compact structure and small floor space. It is easy to install and maintain, and can effectively clean the production equipment such as cylinders, containers and pipelines on-site. The entire cleaning process is airtight. The production equipment, cylinders, containers and pipelines are running, which greatly reduces the chance of secondary pollution.

2. The system can be divided into one to four according to production needs. Especially for two-way and above two-way, it can not only clean the same or more than two areas at the same time, but also can clean while producing during the production process. This greatly shortens the time for CIP cleaning during production.

3. The pneumatic diaphragm pump imported from the United States is used to suck concentrated acid and alkali, which not only improves the integrity rate of the equipment and reduces the maintenance rate of the equipment, but more importantly, it reduces the operating cost.

4. Especially the fully automatic CIP cleaning system, which can automatically detect, add liquid, discharge, display and adjust the cleaning liquid. It is reliable in operation, high in automation, simple in operation, and good in cleaning effects, so it is more in line with modern large-scale fluids Hygienic requirements and production environment requirements for pharmaceutical and food processing technology.

5. Automatically switch the process parameters, automatically adjust the cleaning time, pH, temperature and other parameters.

6. All operations can be recorded to facilitate GMP certification.

7. The fully automatic CIP cleaning system has single tank, double tank and multiple tanks for users to choose, mobile and fixed.

Fully automatic CIP cleaning system cleaning program

Take the beverage industry as an example, the cleaning procedures are as follows:

1. Washing for 3-5 minutes, normal temperature or hot water above 60℃; alkaline washing for 10-20 minutes, 1%-2% solution, 60℃-80℃; intermediate washing for 5-10 minutes, water below 60℃; Finally, wash for 3-5 minutes with clean water.

2. Washing for 3-5 minutes, normal temperature or hot water above 60℃; alkaline washing for 5-10 minutes, 1%-2% solution, 60℃-80℃, intermediate washing for 5-10 minutes, clean water below 60℃, Sterilize for 10-20 minutes with hot water above 90℃.

The cleaning flow guarantee flow is actually to ensure the cleaning fluid flow rate during cleaning, thereby producing a certain mechanical effect, that is, improving the impact force by improving the turbulence of the fluid and achieving a certain cleaning effect.

We will equip customers with corresponding equipment according to their needs, and install and debug the equipment for customers according to the layout of the customer's site to ensure that the equipment can achieve satisfactory results between both parties. Our philosophy is to provide customers with the best quality service and the most reliable products. Any product failures, we will replace and repair them responsibly.

Send a Message

If you want to ask anything just fill in the form below and send us.

Name: Beau time:2020-09-02 10:16:26

A friend recommended this CIP system, he said the equipment is very good.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Top 10 Fishing Tackle Suppliers 2024

- How to Set Up a Fishing Rod for Beginners?

- How to Choose the Best Saltwater Fishing Rods

- HiLaud Promo is a multi-tool promotional items supplier

- Mastering the Art of Tuna Fishing: The Power of Heavy Saltwater Fishing Rods

- What is draft beer?

- Beer fermentation and Degree of fermentation

- Automotive urea production equipment creates value

Contact

- Address : Block B, Headquarters Base ABP,No,2600,Zhuangjian Road,Weifang,Shandong,China

- Tel/Fax : +86-536-8800237

- Email : export@wemac.cn

- Joseph

- WhatsApp: +8617863612639

TAGS

- beer equipment

- craft beer equipment

- craft beer equipment

- beer brewery equipment

- beer brewing brewery

- brewery equipment for sale

- 2 vessels brewhouse

- beer brewing equipment

- beer brewery

- plate heat exchanger

- Gasketed Plate Heat Exchangers

- brewing kits

- beer brewery kits

- home mini beer brew kits

- Yeast propagation equipment

- beer fermenter

- beer bright tank

- top quality beer brewing system

- brewery beer fermetner and bright tank

- brewing equipment for sale

FEATURED PRODUCTS

Professional Industry CIP system Cleaning in place equipment hot sell in Netherlands ZZ

Our CIP cleaning system consists of the following parts. Alkaline water tanks, acid water tanks, disinfection tanks, hot...

More >>

Safe reliable economic and efficient beer brewing CIP system of SUS304 316 from China W1

Safe and reliable. It is equipped with sensors and meters to check and control liquid level and have protection system. ...

More >>

Pharmaceutical cleaning in place CIP system for sale WEMAC S020

CIP system has fixed type and movable type.

CIP system has both automatic mode and manual mode.

We can design it accor...

Durable Automatic CIP cleaning system for sale sterilization equipment WEMAC S004

CIP system has fixed type and removable type.

The control of the CIP system has two mode, automatic mode and manual mod...